Vehicle Manufacturer Recommendations

Be sure to check the OE requirement for each transmission for the exact mileage. In severe duty, the intervals of changes will be shortened.

Fluid

Transmission fluid is a multi-application fluid. It lubricates, is a coolant, and is a hydraulic fluid operation the transmission.

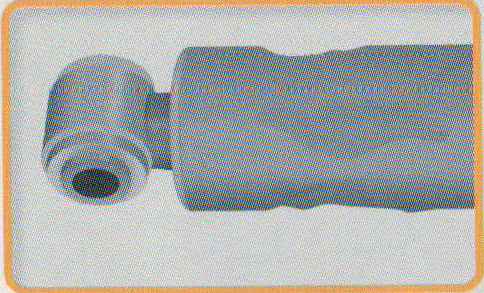

Dirty fluid and filters cause a drop in the fluid circulation rates, causing more heat build-up, which causes the transmission fluid to deteriorate and oxidize, which causes the burnt smell and becomes very sticky. This condition creates excessive wear.

Excessive heat is the number one cause for transmission failure.

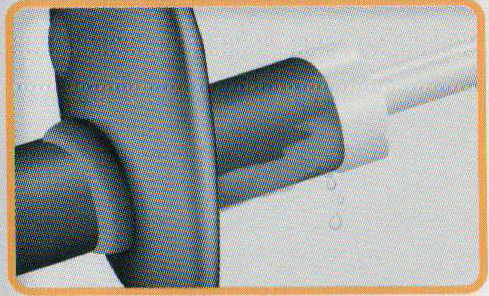

Fluid Restriction

The restriction affects the hydraulic pressure, resulting in slippage leading to accelerated wear on clutches, bands, or other internal components.

Keeping the transmission system clean is very important. Removing any contamination that can interfere with the operation of transmission components, such as valve bodies and solenoids, will promote a longer transmission life.

RSS Feed

RSS Feed